Unmanned Network System of Steel Coke Oven Smart Manufacturing

Publish Date:2021-04-21I. Project Introduction

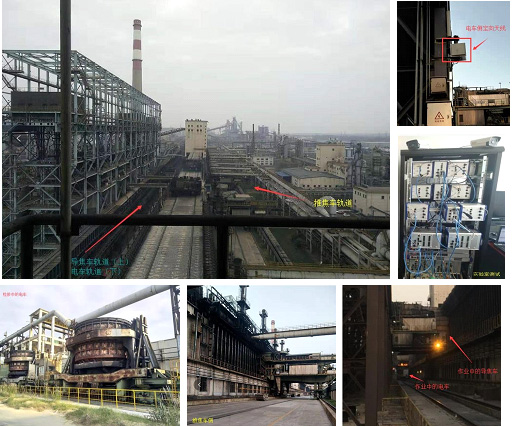

The Phase I and II coke ovens of XX iron works are equipped with three trams (2 duty + 1 standby) to shuttle coke pots. Since the coke ovens were put into use in 2015, the semi-automatic production mode mainly relying on manual operation and coordination has not only resulted in heavy workload, but also posed potential safety hazards, which greatly limits the utilization of the equipment and systems. According to Baosteel's requirements for smart manufacturing planning, unmanned retrofit of coke oven trams to realize automated unmanned operation will greatly lower the labor intensity of field personnel, reduce production accidents caused by manual misoperation or intervention, and further improve the operation efficiency and production stability of equipment. This project mainly includes the retrofit of control system and the addition of industrial television system.

The unmanned project of coke oven smart manufacturing concerns four types of heavy-duty vehicles: 3 coke transfer trams, 3 coke guides, 3 coal chargers and 3 coke pushers. Except the coal chargers, all other three types of vehicles need to be installed with wireless devices for network coverage. The four-car linkage and sharing of monitoring videos and images are realized through wireless transmission. The control authority of the tram is released to the coke guide, and the operation of the tram is controlled from the coke guide to downsize staffs and improve efficiency.

II. System Architecture

IV. System Application Requirements

Ø Dual-channel wireless is required, one channel for transmitting control signals and the other for transmitting video signals;

Ø Control data and video data should not conflict with each other or seize bandwidth resources;

Ø The field strength of control signal at each point in the covered area should be ≥-65dB, with a packet loss rate of ≤5‰ and a delay of < 100ms;

Ø A wireless average bandwidth of ≥ 20M is required for video signal, so as to support the simultaneous transmission of 8 channels of 720P video;

Ø The wireless roaming time of video signal and control signal should be ≤ 50ms;

Ø Since the field wireless environment is complex, the equipment should have solid anti-interference ability;

Ø On-site outdoor installation requires wireless AP to have good seismic resistance and IP67 protection level;

VI. Solution

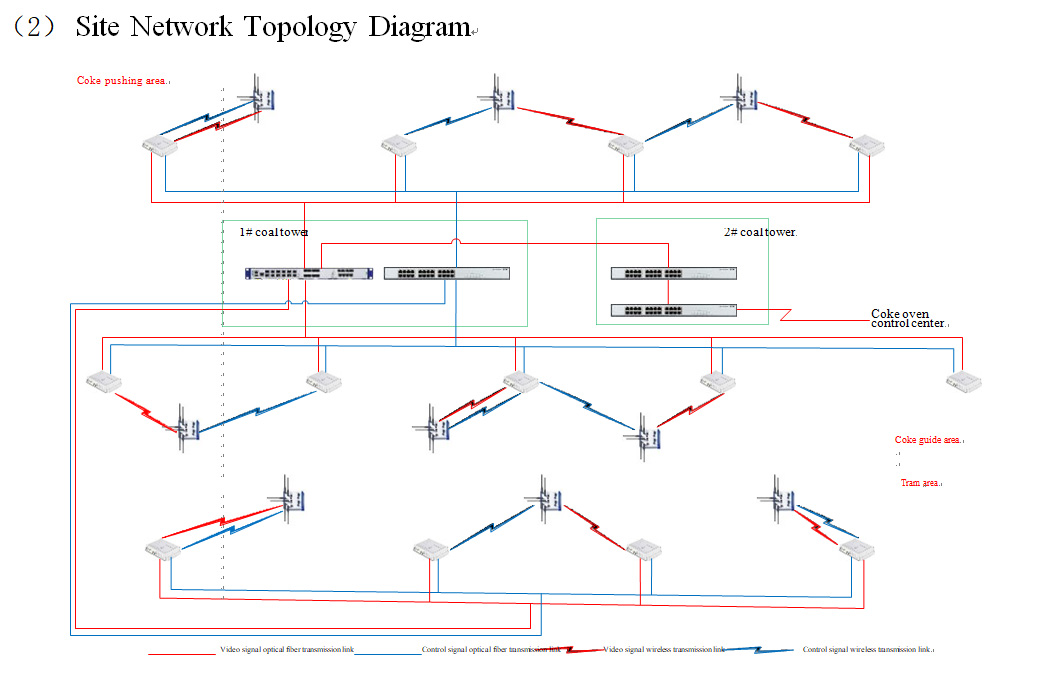

In this solution, a Hirschmann layer-3 switch GRS1042 is deployed in 1# coal tower for video transmission, so as to realize the connection with H3C switches of 2# coal tower and coke oven control center, and an H3C switch is deployed for transmission of control signals;

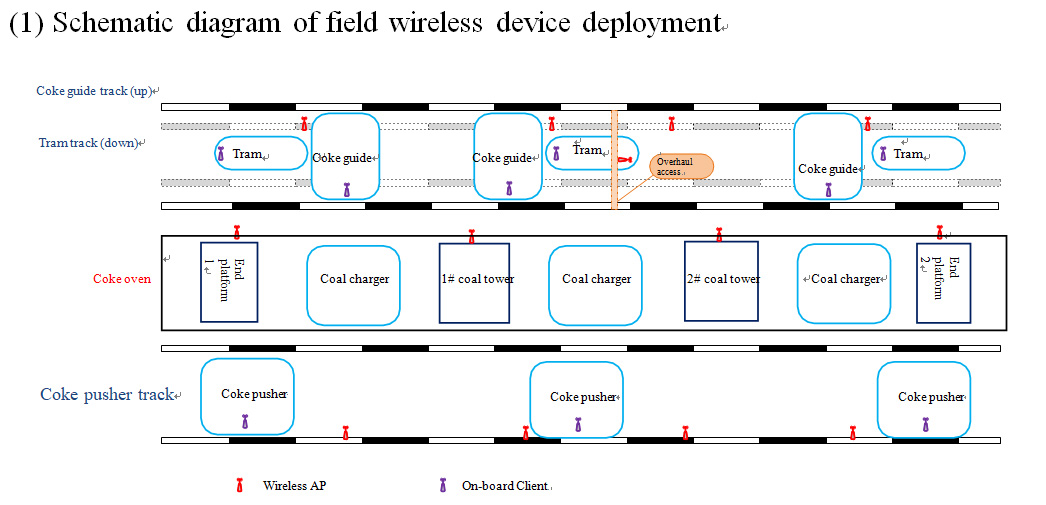

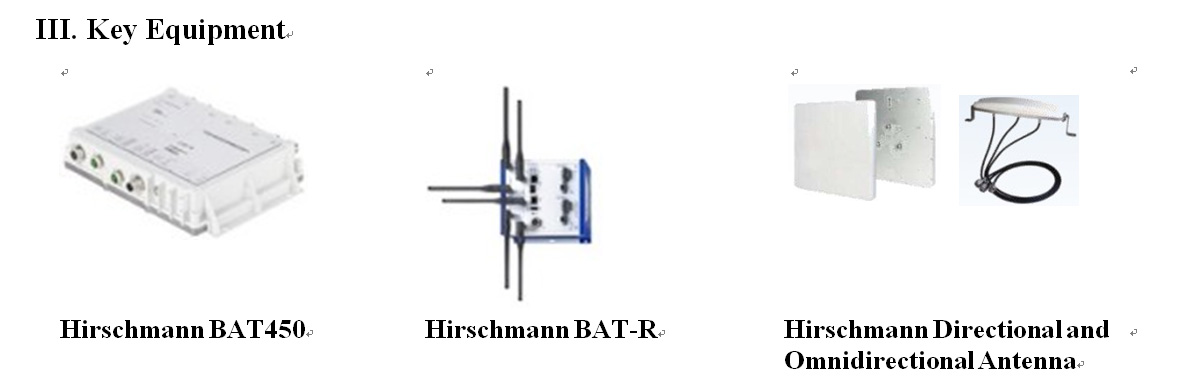

According to the investigation of the site environment, the site is divided into three areas: coke pusher area, coke guide area and tram area. To this end, hierarchical design is applied to solve the site occlusion. 4 wireless APs are deployed along the tram track in the tram area, which are covered by Hirschmann directional antenna; since the coke guide area is relatively open, 1# coal tower, 1# end platform, 2# coal tower, 2# end platform and intermediate Overhaul access are covered by Hirschmann omnidirectional antenna; 4 wireless APs are deployed along the coke pusher track in the coke pushing area, which are covered by Hirschmann directional antenna. All AP points are laid with 8-core optical fibers to connect with 1# coal tower, so as to lay a foundation for dual channels.

All Hirschmann wireless devices are equipped with dual channels, namely, two groups of WLAN and two groups of LAN ports. Through reasonable configuration, WLAN1 of the wireless device, corresponding to the LAN1 port, transmits control signals to the H3C switch of 1# coal tower; WLAN2 of wireless device, corresponding to the LAN2 port, transmits video signals to the Hirschmann GRS1042 switch of 1# coal tower, and the Hirschmann switch is subjected to a series of optimized configurations to communicate with the coke oven control center. Through the QoS of wireless AP and switch, control data and video data will not seize the same limited bandwidth resources.

u VIII. Project Acceptance Test

During the project acceptance stage, Hirschmann's wireless transmission is stable with a performance beyond the user's expectation, getting ahead of other projects in the industry and reaching top level of the industry. In this project, the packet loss rate of control signal is < 2‰, and the tested average wireless bandwidth of video signal transmission is 30M.

II. System Architecture

(1) Schematic diagram of field wireless device deployment

Coke guide track (up)

Coke guide track (up)

|

||||||||||||||

|

|

|

|

|||||||||||

|

||||||||||||||

Tram track (down)

Overhaul access

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Coke oven

Coke oven

|

|

|

Coke pusher track

![]()

![]() Wireless AP On-board Client

Wireless AP On-board Client