Industrial Network Scheme of in Cigarette Factory

Publish Date:2021-04-21I. Project Introduction

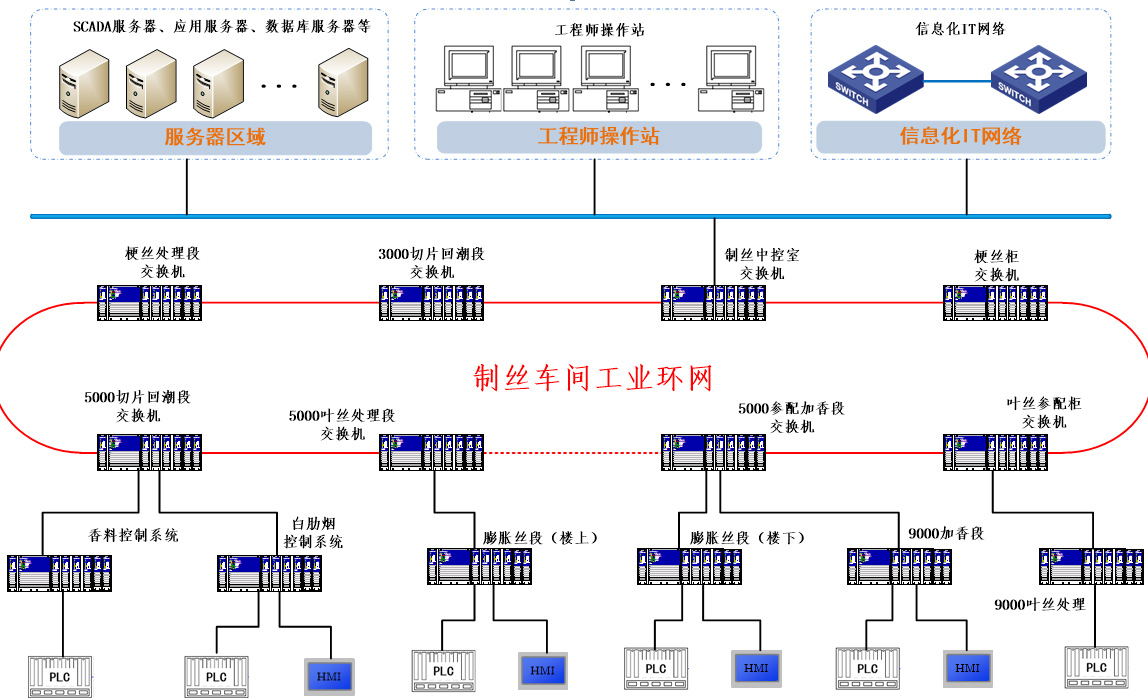

The backbone network of tobacco shredding workshop in XX Cigarette Factory was built in 2009. The industrial control network system of tobacco shredding workshop is the bridge among equipment control system, production management system and production control system. With I/O server as the core, the system connects the main control PLC of each production line of tobacco shredding workshop, each control section and the main control PLC of stand-alone control system with I/O server through industrial Ethernet, so as to realize convenient and quick data exchange. The I/O server then provides the collected data to workshop database server, supervisory computer and field operation query terminal for centralized monitoring and information query.

Tobacco shredding is the first working procedure of production and processing in cigarette factory, which involves 40 processes and 120 indicators. Moreover, the tobacco shredding workshop has the characteristics of wide processing area, various equipment and difficult control. Therefore, the network adopts Ethernet transmission with good openness and wide application, so as to transmit various data collected on site to the server. In order to ensure the reliability of the network, the ring network is adopted as the framework of the workshop backbone network.

II. System Architecture

III. Key Equipment

IV. System Requirements

u According to the communication requirements of network sites, the system adopts ring network architecture. Any failure of any physical link in the ring network will not affect the stable transmission of the system;

u Ring network self-recovery time < 50ms;;

u The network adopts 1000M uplink and 100M access to ensure the requirements are satisfied;

u The network is designed according to the concepts of advancement, feasibility, security and reliability, and is upward compatible;

u The equipment adopts fanless design, DIN rail installation and modular switch. Each module supports hot plugging for easy extension, and 20% of the ports are reserved;

u The switch supports multiple management modes, and the configuration and maintenance interface is simple and easy to operate;

u Network management software is used to monitor and manage the whole network. The interface of network management software must be simple and user-friendly, and support visualized management and automatic generation of topology and various fault alarms.

V. Solution

A Hirschmann MS4128 rail-type modular switch is deployed respectively at the convergence points in tobacco shredding central control room, stem shred cabinet, leaf shred blending cabinet, 5000 blending and flavoring section, 5000 leaf shred processing section, 5000 cutting and damping section, stem shred processing section, and 3000 slice cutting and damping section. The switches are connected end to end through 1000M ports to form a 1000M industrial Ethernet transmission ring network. The spice control system access switch, burley tobacco control system access switch, expanded tobacco section access switch, 9000 flavoring section access switch and 9000 tobacco shred processing access switch are linearly connected to the industrial ring network nearby. A set of Hirschmann Hivision network management software is deployed in the central control room to realize real-time monitoring of the network.

Reasonable configuration is carried out on the 1000M industrial ring network switches and access switches of tobacco shredding workshop, so that the main control PLC of each production line, each control section and the main control PLC of stand-alone control system and I/O server can realize convenient and quick data exchange, and meet the construction requirements.

Rail modular switch Rail modular switch

MS4128 MS30